Brass Casting

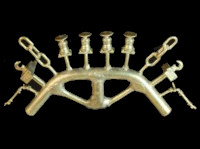

Brass cast model railway air horns.

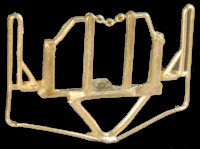

Brass cast brake wheels 1:87 scale

Brass cast model railway signal finials.

Brass cast model railway parts.

For several years Ornamental Castings has been manufacturing small scale model parts in lost wax brass. Some of the

Uneek range of model railway parts have components made of brass.

In some circumstances model parts require strength and high durability. This can be a problem when white metal or resin

parts are used. Brass castings give the model strength and have the benefit of being able to be soldered to other parts

of a model, rather than glued.

With years of experience gained working in the jewellery trade, John is putting his knowledge to use to manufacture model

parts using the lost wax casting process. It is an age-old technique where wax patterns are made of the original masters

and then encased into a plaster-like material called investment. A flask containing the investment is heated over many

hours to melt the wax patterns out of the investment. When the wax patterns have melted and burned away and the flask is

at the right temperature the flask is placed into a vacuum chamber and molten brass is poured into the now-empty cavities

to produce the castings.

A disadvantage of brass casting is the cost. Lost wax brass castings are much more expensive to produce than white metal

castings. There are also limitations on the size of parts that can be manufactured and casting runs may be subject to a

minimum number of items depending on their size. John can produce brass castings from your own modelled masters or from

commercially made rapid prototyped masters. For more information about casting parts in brass, feel free to

contact John and make enquiries.

Brass casting tree.

Brass casting tree.

Brass cast model railway parts.

Brass cast model loco front handrail.