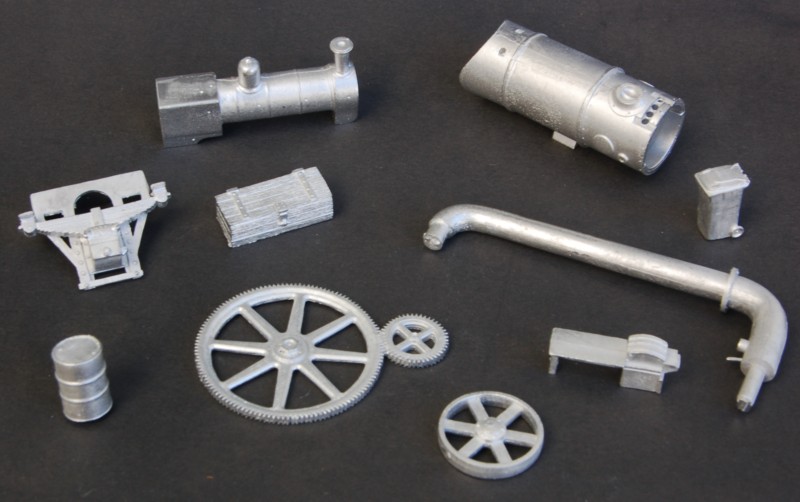

White Metal Casting

White metal mould preparation.

White metal castings.

Better known as rubber mould spin casting, this is a process that allows low temperature pewter alloys to be cast into rubber moulds.

Black organic or silicone rubber moulds are made by vulcanising detailed master patterns between two rubber discs. Each cavity in the rubber mould

has a runner cut to it, to allow metal to feed into the cavity from a central sprue.

The mould is placed into a casting machine that spins the mould at high speed. Metal is poured into the centre of the mould as it is spinning and

the centrifugal force throws the metal down the runners into the model cavities. Ornamental Castings have been utilising this casting process to

produce fine detailed model castings for 20 years.

If you require detailed model parts similar to those pictured below for a model project of your own, or you are embarking on producing model kits

etc. John can produce white metal castings from your own modelled masters or from commercially made rapid prototyped masters. For more information,

contact John and discuss your requirements.

Various white metal castings in N scale, HO scale and O scale.